A Comprehensive Guide to Sustainable Fabrics

Go green with your clothing and home textiles.

Buying clothing and other textiles made with sustainable fabrics that are processed both ethically and responsibly is vital to the health of our planet. The fashion industry alone is responsible for 10% of global carbon emissions.

Discover sustainable clothing and home textile options here.

What are sustainable fabrics?

This is the million dollar question with a very complicated answer. There are several important factors that make up a truly sustainable fabric:

- Material type, including its sourcing

- The dyeing and finishing processes used

- Labor practices

These are important things to consider because of the huge environmental and ethical impacts created by the production process of these materials. The fashion industry is responsible for almost 10% of global emissions and is on pace to double by 2030. Americans toss an estimated 11.3 million tons of textile waste, or 2,150 pieces of clothing per second, into landfills every year. And both humans and animals alike are exploited within the industry.

The simplest way to classify types of fabric is by dividing them into two groups: natural fibers and man-made fabrics, with an additional group that’s a hybrid of both.

Natural plant-based fibers

Plant-based natural fibers are some of the oldest materials used by humans, but throughout the last century has been largely replaced by synthetic fibers, which makes up the vast majority of clothing today.

Natural are ultimately the most sustainable fabrics because they are both renewable and biodegradable; however, the degree of eco-friendliness is much more complicated. This is further determined by each stage of production, starting with the manner in which their parent crops are grown, processed, and produced.

Concerns include land and water requirements, use of chemicals like fertilizers and pesticides, and ethical labor. Natural animal-based fibers create their own set of potential issues, namely humane treatment and environmental impacts.

Methods used during the manufacture of natural fiber fabrics are also important to determine the sustainability of clothing and other textiles made from these natural materials. Ideally this involves non-toxic processes with a low environmental impact. When considering end of life for these goods, those made from natural fibers hold the ultimate edge over synthetic materials. Products made from raw materials that grow in nature are biodegradable, while the latter are incinerated or dumped in landfills, possibly generating toxic byproducts.

There are numerous types of natural fibers used in textiles, from everyday materials such as cotton to those you have probably never heard of. Any of these plant-based fabrics are made from cellulose, a polysaccharide (a carbohydrate compound) that is obtained from plant fibers, usually bark, wood pulp, plant stalks, or leaves.

Let’s review the most common types of natural fabric you will encounter and what to look for when purchasing.

Bamboo fabric

Contrary to popular belief, bamboo is not a tree; it is a grass that is the fastest growing plant on Earth. Some varieties can grow approximately two inches per hour, possibly reaching 60 feet in only 3 months! And it doesn’t require pesticides or fertilizers to do so. It also doesn’t require supplemental irrigation, as it is able to survive on rainfall alone. Bamboo also requires less land degradation compared to logging, and improves soil quality and erosion. A bamboo forest absorbs five times more carbon and produces 35% more oxygen than a similar stand of trees.

These qualities make bamboo very sustainable material, but with some caveats. When grown and manufactured properly, bamboo fabric can be one of the most eco-friendly fabrics available. So what is the best practice?

Bamboo becomes unsustainable when trees are cut down to clear land for its growth. This leads to biodiversity loss and displacement of local wildlife, compromising ecosystems. This loss of biodiversity also results in the bamboo being more susceptible to pests, which in turn increases the chances that farmers will use pesticide control.

Look for Forest Stewardhip Council (FSC) certification on bamboo products to ensure sustainable sourcing.

Bamboo used for building materials and housewares undergoes a much more straightforward mechanical process to produce. With FSC or similar certification, bamboo products are among the most sustainable options available. However, transforming bamboo fiber into fabric is another story. These fibers can be processed one one of two ways: mechanically or chemically. Is it surprising to know that the method that is worse for the environment is also the one most commonly used?

Bamboo processing

According to FTC regulations, “unless a product is made directly with bamboo fiber — often called “mechanically processed bamboo” — it can’t be called bamboo.” This agency has been cracking down on product labeling in recent years.

“The truth is, most ‘bamboo’ textile products, if not all, really are rayon, which typically is made using environmentally toxic chemicals in a process that emits hazardous pollutants into the air. While different plants, including bamboo, can be used as a source material to create rayon, there’s no trace of the original plant in the finished rayon product.”

Federal Trade Commission

Mechanical processing is performed in a similarly to flax or hemp, resulting in a fabric sometimes referred to as bamboo linen. Unfortunately, being costly and time-consuming, this type of production is rare and results in a coarser fabric.

This leaves you with bamboo viscose or rayon which, as mentioned, is heavily processed with toxic chemicals. The National Resource Defense Council recommends Lyocell processed rayon fibers made from bamboo instead. More on lyocell in the semi-synthetic section below.

An additional consideration with bamboo products is its carbon footprint from shipping. Generally, 80% of bamboo forests are in Asia; the remaining 20% comes from Africa and Latin America. Some companies offset the shipping footprint by donating to carbon positive projects.

Go Green

Purchase bamboo clothing and other textiles certified by the FSC and either mechanically produced or made with Lyocell bamboo fibers.

Coir

Most of the world’s coir is supplied by India, Sri Lanka and Vietnam. Coconut trees are quite drought tolerant and thrive in salty, sandy soils like those found in coastal areas. All parts of the tree and fruit are useful.

Coconut cultivation can face the same environmental woes as palm oil, such as deforestation and monoculture farming. In fact, a controversial 2020 study found that the production of coconut oil threatens five times more species per ton of oil produced palm oil and more than any other cooking oil.

There is not a wide variety of data concerning pesticide use in coconut production, although there are some studies that have found pesticide residues in coconut oil and water.

The best quality coir is obtained through a biological process called retting, where coconuts are soaked in brackish seawater for around nine months. During this time, microorganisms separate the coir fibers, as well as the coir pith, which is commonly used in gardening applications.

After the coir fiber is harvested, it is woven into lightweight yet strong yarn. This underutilized fiber is often used to produce home textiles such as floor mats, brushes, and mattresses.

Go Green

Coir is an eco-friendly fiber choice, and generally inexpensive.

Cotton

Cotton has many benefits: it’s easy to clean, soft, durable, lightweight, breathable, and absorbent. This natural material is cheap to produce and is biodegradable, compostable, and recyclable. It’s easy to see why cotton accounted for 22% of all fiber production in 2021 and is the most abundant non-food crop grown. On the surface, this versatile natural plant fiber seems like it might be one of the best sustainable options. However, there is an astronomical amount of conflicting data or misinformation about cotton, and the lack of transparency among farmers or producers complicates the issue.

India produces the most cotton in the world, followed closely by China; these countries are the top two users of raw cotton. China is by far the world’s leader in processing raw cotton fiber into textiles and apparel. The United States ranks third in global cotton production. Domestically, this crop is grown across 17 southern states, aka the “Cotton Belt”, from California to Virginia, with Texas being the largest producer.

World’s dirtiest crop?

Cotton has been referred to as the “world’s dirtiest crop” because of reportedly high use of fertilizers and pesticides. Just how much of these chemicals are being used is anybody’s guess, as it seems reported data varies wildly. Every farm may operate differently and regulations differ between countries. The biggest gaps are related to pesticide use, according to Forbes, because pesticide usage data is either not reported, or privately owned, and costs an unfeasible amount of money to access for single stakeholders.

I’ve come across claims that anywhere from 16 to 25% of the world’s insecticides are used on cotton. According to the International Cotton Advisory Committee (ICAC), cotton accounted for 4.71% of all the pesticides and 10.24% of all insecticides sold globally in 2019. Note this data is for chemicals “sold” and not “used.”

As for cotton produced in the United States, it is very likely that these chemicals have been used. The USDA’s National Agricultural Statistics Service (NASS) conducted a 2019 Agricultural Chemical Use Survey. During that planting year, cotton farmers applied nitrogen fertilizer to 86% of planted acres. Phosphate was used on 61%, potash 48%, and sulfur 41%.

The NASS found herbicides were the most extensively utilized chemicals, with application to 93% of planted acres. Glyphosphate, the controversial chemical found in Roundup, was the top choice and continues to grow in usage each year. Other chemicals such as fungicides were applied to 65% of planted acres, while insecticides were used 56% of the time.

Effects of heavy fertilizer and pesticide use

Synthetic fertilizers, which are widely used to increase production, result in water contamination as well as significant greenhouse gas emissions through both their production and in-field use. Arguments for using large amounts of fertilizers is that without it, crop yield is significantly lower and the cotton industry wouldn’t be able to keep up with the demand. (Another reason fast fashion is so harmful.)

Pesticides contaminate the soil as well as ground and surface water, and drift onto nearby crops. According to the Center for Biological Diversity, “As little as 0.1% of an applied pesticide interacts with its targeted weed or pest. The remainder contaminates the soil, air and water and can have significant impacts throughout the ecosystem. Pesticides can also linger in the soil for years or decades after they are applied, continuing to harm soil health.” Pesticides, including the aforementioned glyphosate, have been associated with numerous adverse health effects.

Water consumption

Cotton is considered a thirsty crop: its cultivation accounts for about 69% of the textiles industry’s fiber production water footprint. Dyeing cotton fibers is also very water intensive. The UN estimates that almost 1000 gallons of water is needed to produce just one pair of jeans. Manufacturing a single cotton T-shirt uses 2,700 liters of water, and a single kilogram of cotton fiber requires more than 20,000 liters of water to produce.

Types of cotton

There are two main species of cotton: upland cotton and extra-long staple cotton. The main difference between species is fiber length.

Upland cotton comprises the vast majority–97%— of all production.

Extra-long staple varieties of cotton are Egyptian, Turkish, and in the United States, Pima cotton. These longer fibers are more expensive than upland cotton and are valued for their strength, softness, and color retention. They are also easier to recycle afterlife due to their longer fibers. But Pima cotton tends to require more water and yield less per acre than upland cotton.

Is organic cotton more sustainable?

Organic cotton accounts for only 1% of all cotton grown. There is some controversy whether organic cotton is more sustainable than conventionally grown.

One such argument is regarding water use. Some sources say that organic cotton uses 91% less water than regular cotton, but a report released by the Transformers Foundation disputes this. Of note, this organization states that their report was encouraged by Cotton Incorporated, National Cotton Council, and the American Cotton Shippers Association, all cotton industry organizations. In any case, the amount of water savings varies on farming region and practices.

Regardless of the exact amount of water saved by the cultivation of organic cotton, the lack of synthetic chemicals used is alone huge advantage, leading to decreased levels of pollution as discussed above.

In addition, the The World Counts reports that organic cotton vs cotton has:

- 62% lower energy demand

- 46% lower CO2-emissions

- 26% lower soil erosion

Go Green

While not perfect, organic cotton fabric is the superior choice when it comes to cotton. Look for organic cotton clothing and other textiles that are certified by Global Organic Textile Standards (GOTS). Unfortunately, organic cotton is often significantly higher priced than other cotton. Another certification that may be more accessible to a broader range of people is the Better Cotton Initiative (BCI). While not necessarily organic, this cotton is grown by farmers who have committed to upholding standards that:

- minimize the harmful impact of crop protection practices

- use water efficiently and care for the availability of water

- care for the health of the soil

- conserve natural habitats

- care for and preserve the quality of the fiber

- promote decent work

Hemp

Hemp is one of the oldest fibers in human history. It is categorized as a bast fabric, which means it comes from the stem of the plant; in this case cannabis sativa. Hemp contains only 0.3% THC, while recreational marijuana usually has 15-25%. Yet, farming of this crop was restricted in the U.S. through much of the 20th century until October 2019, and is still only legal to grow in 37 states.

These regulations have resulted in hemp fabric being highly underutilized, despite being one of the most environmentally friendly natural fibers in the world, and one of the most versatile.

- Hemp plants have carbon sequestration abilities–so much that they are carbon negative

- Does not require fertilizer, additional irrigation, herbicides, or pesticides and has a noticeable resistance to rodents, fungus, and many types of weeds

- Improves soil structure and nutrition, can absorb pollutants from the soil

- Adapts easily to different climates, resulting in a wide geographical range of cultivation

- Short cropping period (70–90 days) and has a lower chance of crop failure than flax

Compared to cotton, hemp cultivation:

- Requires about 77.6% less cost in fertilization, seeds, field operation, and irrigation costs than cotton

- Requires 50% less water

- Has a much higher yield: an acre of hemp can produce 2-3 times more fiber than an acre of cotton.

Hemp is processed chemically or mechanically, much like bamboo. And as with bamboo, mechanical production is best, but is more time-consuming and expensive. Organic is also the better choice, of course.

Hemp fibers exhibit several distinctive properties that set them apart from other natural fibers. These include their aseptic characteristics, high absorbency, protection against UV radiation, resistance to mold and mildew, and absence of allergenic effects.

Go Green

Organic hemp is one of the most sustainable textile fibers available.

Jute

Primarily grown in India and Bangladesh, jute fiber is collected from the bast, or skin, of the jute plant. This crop, typically grown through a simple cultivation process without the use of pesticides or fertilizers, requires a lot of rainfall and a warm, humid climate.

Jute fiber is very strong and durable, with a natural look and feel. It has high density, heat resistance, and moisture retention. It is commonly used to make twines, ropes, and mats but also can also be used for home textiles such as curtains and carpets. It’s one of the cheapest natural fibers and the most widely used globally after cotton, accounting for 50% of all other plant-based materials.

In the Handbook of Natural Fibres (2020), the author states, “Viewed in the light of current global concern of widespread pollution arising out of use of plastics, promotion of innovative development of products of daily necessities from renewable and biodegradable materials such as jute and coir fibres has become imperative for the very sustenance of life on earth.”

Go Green

Jute is a great, environmentally friendly fiber and is also generally inexpensive.

Linen (flax)

Linen is an ancient natural fiber made from the flax plant, used long before cotton. Flax can grow in poor-quality soil and usually does not require any chemical pesticides. Its cultivation does not require a lot of irrigation and in many cases grows on natural rainfall alone. Linen production uses the whole flax plant, leaving no waste. These qualities, in addition to being fully biodegradable and easily recycled, makes it one of the most sustainable fabrics in the world.

80-85% of flax is grown in Europe, primarily France and Belgium. Only 0.5% of this crop is grown organically. The downside is that it tends to be expensive because it is difficult to weave, making it labor intensive.

Go Green

Linen is extremely durable and long-lasting, making it great sustainable fabric choice.

Less common sustainable natural fibers

Some plant-based fibers have been used for centuries in other parts of the world, while others are recent innovations being developed by sustainability-minded companies.

Abaca

Abaca, also called Manila hemp, is created from the fibers of the abaca tree, which belongs to the banana family. This plant is native to the Philippines, where it has been handwoven for generations. Traditionally it has been dyed with plant-based natural colors.

An extremely versatile fabric, abaca is commonly used in the Philippines and other eastern countries for clothing, footwear, accessories, and home textiles. The fiber is so durable that it is often used for rope, cords, and strings, and even rigging on ships.

This fabric has been branded Bananatex.

Kapok

You may not have heard of kapok, which has been described as having the smoothness of silk and the fluffiness of cotton. This fiber is harvested from the seeds grown on the tropical Kapok tree, fast-growing trees that can grow up to 13 feet each year until reaching a height around 164 feet.

Kapok is a vegan alternative to down, often used to fill pillows, bedding, and upholstery. Due to lack of strength and elasticity, kapok fiber cannot be spun into fabric and must be blended with other materials. It has natural water repellancy and oil absorbency properties. When used alone, it is hypoallergenic and grown without the use of pesticides.

Pineapple Leaves

Pineapple is one of the most productive tropical fruit crops in the world; one acre of pineapple plantation can produce 20,000 fruits every 15 months.

Typically, after harvesting the fruit, the leaves are either burned or left to decompose. A company called Ananas Anam sought a sustainable alternative to this practice by developing Piñatex, a leather-like material made by extracting cellulose fibers from these leaves. This innovation offers a vegan fabric alternative by utilizing a byproduct of the existing fruit industry, eliminating the need for additional land, water, or pesticides. Furthermore, it provides farmers with an additional source of income by allowing them to sell leaves suitable for fiber production.

Seaweed

SeaCell is a branding of lyocell fiber that uses brown algae from the ocean in its production. The resulting fabric contains 19% of this algae and 81% lyocell. (Read more on lyocell below.)

The fabric is home compostable, verified by a TUV Austria certification, and has OEKO-TEX certifications as well. There are many claims made of the health benefits of wearing this clothing, none of which has any scientific backing. But with sustainable sourcing of this plentiful plant, along with a closed loop production system, it is a very promising sustainable fabric.

Animal-based materials

Materials that come from animals have varying levels of environmental impact related to the farming/ranching practices. Some sheep raising leads to land degradation, and raising cattle has significant environmental impacts, including deforestation and greenhouse gas emissions.

These products are very environmentally friendly when it comes to end of life. These materials are durable and long lasting, in addition to being biodegradable and often recyclable.

Another important concern with animal products is ethical treatment, which is cause for some people to avoid buying any of these products altogether. Whether you fall into this camp or not, make it a priority to choose products that are transparent about animal welfare and are certified cruelty-free. These certifications are by no means perfect, but are probably the best resources available to consumers.

Down

Down brings to mind cozy comforters, soft pillows, and warm, puffy winter coats. The feathers that fill these items are known for their superior insulating quality while being lightweight and breathable.

These fine feathers are found under tougher exterior feathers of geese and ducks.

Waterfowl are not raised strictly for down, but rather the feathers are collected for from birds raised for meat, ideally after they have been slaughtered. However, some suppliers engage in plucking the feathers from live birds, akin to pulling out hair. This painful practice is illegal in the EU but in the US, laws are more ambiguous. China supplies at least 80% of the world’s down supply, and they have no regulations in place.

In addition, some operations are known to force-feed birds to fatten up their livers for foie gras.

The Responsible Down Standard was started by the Textile Exchange and supported by companies like The North Face and Patagonia. The presence of this certification denotes ethically sourced down from suppliers that do not engage in these or other unethical practices.

Recycled down is another option. Patagonia is a good example of a company using recycled down in some of their products.

Go Green

Buy products made with recycled down or ethical down certified by the RDS.

Fur & Leather

Most leather comes from animals raised for meat, making it a by-product of that industry, but not all.

Furs are just the opposite: most come from animals raised specifically for their pelts or fur. Even if you are not strictly vegan, I believe we should refrain from buying these products that came from animals solely raised for this purpose. But there is much more to buying ethical leather, if there is such a thing.

Two-thirds of hides used for leather comes from cattle, followed by sheep and goats. Raising cattle is one of the most harmful activities to our planet today. This industry is the leading cause for deforestation around the world and is a huge source of greenhouse gas emissions. Read more about this in my blog post The Big Beef with Cattle’s Environmental Impact.

Go Green

Avoid furs and hides from animals raised strictly for supplying material for clothing and accessories.

Silk

About 75% of silk is produced in China, with the majority of the remainder made in India; these two countries account for 96% of silk worldwide. Unfortunately, the production of this beautiful, biodegradeable fabric is marred by several serious problems.

Animal cruelty issues

Silk is made by silkworm larvae, which have been domesticated for centuries; as a result of this longtime genetic breeding, wild populations became extinct, probably because farmed silkworm moths no longer have the ability to fly.

After eggs laid by silkworm moths hatch into larvae, they which feed voraciously on mulberry leaves for about 42 days, molting several times in the process. After this feeding stage, the caterpillars form their silk cocoons with a single continuous strand of silk, which reaches about 1,000 feet in length.

During this pupal stage, the cocoons are harvested and most often submerged into boiling water or steamed to loosen the silk thread while preserving material quality, thread length, and value. This of course kills the silkworm pupa inside. It take around 6,600 of these pupa to produce one kilogram of silk.

Ahimsa silk, or peace silk, has been touted as a more ethical silk, but unfortunately, the process used in the production of this type of silk is not much better. While this method allows the silkworm to complete its pupal cycle, maturing into a moth and leaving the cocoon before it is processed, the moths are often destroyed soon after, according to the animal rights organization Beauty Without Cruelty India.

Environmental impacts of silk production

The silk industry has a very high carbon footprint, starting from the beginning.

Mulberry leaves are the primary food source for silkworms. Normally, these plants are very sustainable, being fast growing and drought-tolerant, while having a strong ability to absorb greenhouse gases. But in the case of large scale mulberry production, there is a good chance a fair amount of synthetic fertilizers and pesticides are being utilized.

Silk production itself uses a lot of energy. Farms require temperature control along with energy use to heat the boiling water for cocoon harvesting. This process, along with the dyeing stage, uses a large amount of water. In addition, numerous chemicals are often used to clean and dye silk, which pollutes local water and hinders the fabric’s biodegradability.

Human exploitation in the silk industry

Silk factories have a history of child labor as well as slave or forced labor, as this 2021 CNN article describes. Processing silk is very labor intensive, and workers may not be adequately compensated for their labors. In addition, these workers are often exposed to toxic chemicals and are at risk for burns from the boiling water or steam used to separate cocoon silk.

Silk alternatives

Organic silk is available, but that doesn’t necessarily mean that ethical production methods were used.

Wild silk, also known as Tussah or Tussar silk, comes from cocoons harvested from forests after moths emerge, and is a potential ethical alternative. However, regulation of this industry doesn’t really exist, and some producers may gather cocoons from the wild only to boil ones containing pupa just like the traditional process.

Lotus silk is a rare, extremely expensive plant-based silk.

Artifical silk, using materials such as polyester or rayon, is an ethical and inexpensive vegan alternative to silk, but synthetic materials like this are essentially plastic that creates significant environmental issues, as discussed below.

Go Green

Truly sustainable silk is hard to come by, and is best avoided in favor of other more eco-friendly and ethical alternatives.

Wool

You probably automatically associate wool with sheep, but wool actually refers to the fiber that comes from a variety of additional animals. Animal wool is sustainable because it is biodegradable and renewable. It is durable and has natural properties that include antimicrobial, anti-odor, flame and water resistant. The biggest concern with wool is animal welfare.

Sheep

Domestic sheep do actually need to be sheared at least annually for their health. They do not naturally shed their winter coats, and so any subsequent growth just adds to the existing fleece. This puts them at risk for overheating in the summer, creates extra weight that affects their mobility, and makes them more susceptible to parasites and disease.

The manner in which they are sheared, and raised, is a consideration. Look for products and companies that are certified by the Responsible Wool Standard, a third party certification. Some specific types of wool have their own certifications as well, which are listed below.

Sheep do contribute to GHG production, but nowhere near cattle. A sheep can produce about 30 liters of methane per day while a dairy cow can create up to 200.

A Note on Paloma Wool

Paloma Wool is actually a brand, not a type of wool. Their website is littered with sustainable buzzwords but has no sustainability information of value. A quick glance at their products shows they use a fair amount of synthetic fibers in their clothing. good on you rates them at a 2/5, or “not good enough” on their sustainabiity scale. Skip this brand.

For a deeper dive on wool, read my post, From Sheep to Sweaters: Is Wool Sustainable?

Alpaca

There are two species of alpaca: Huacaya, which 95% of alpaca wool comes from, and Suri. These animals are some of the oldest domesticated species in the world. 80% of alpaca wool comes from Peru.

According to the Daily Beast, “It’s not just the fiber’s high quality and earning power that the Peruvian government touts; it also has the power to help the country’s indigenous populations, many of whom suffer from poverty. At least 50,000 families in the Andean highlands rely on herding alpaca for income and to sustain themselves.”

There is less concern for animal mistreatment with alpacas than other wool animals. According to the Council of Fashion Designers of America (CFDA), most alpacas live free-range in their native habitat in the Andes Mountains.

Characteristics of alpaca

- Alpaca’s feet have soft pads rather than hooves, which doesn’t cause land degradation.

- Goats pull up plants by the roots when they graze, whereas alpacas only eat the leafy part of native grasses, allowing plants to regrow.

- Alpacas eat only 1-2% of their body weight each day, compared to cashmere goats 10%.

- Compared to goats, alpacas consume a small amount of water.

- Their waste can be used as fertilizer.

- Alpacas are shorn once a year just before the hot summer months, and this can yield enough wool to produce 4-5 sweaters, while a cashmere goat need 4 years to produce only 1 sweater.

- Because alpaca is naturally odor resistant and somewhat stain resistant, it does not require frequent washing, and usually be hand washed. It is also resistant to wrinkling and recovers from wrinkles well, so very little ironing is required.

These distinctions make alpaca wool is much more sustainable alternative for cashmere as they have significantly less environmental impact than cashmere goats.

Another bonus is that alpaca wool does not contain any lanolin or oil, making it hypoallergenic, pill less, and eliminates the need to be processed with chemicals. It is very durable, breathable, and moisture wicking.

Angora

Angora wool comes from any of the four species of Angora rabbit. This wool has been the center of animal cruelty claims. In 2013, PETA released a graphic video of these rabbits taken from cramped, filthy cages to have their fur ripped off their body, leaving a bloody mess behind. (I’m only repeating a summary of the video, as I don’t want to watch it myself.) This resulted in many designers removing Angora from their clothing lines.

At least 90% of Angora comes from China, which does not have any animal welfare laws. It is possible to source ethical Angora, but it takes some diligence and research to find companies that source their angora wool from small farms that raise the animals in an ethical, humane manner. Because of this, it might be best to stay away from this type of wool.

Angora rabbits do rely on regular grooming and shearing to maintain their health and prevent matting of their coat. Angoras molt several times a year, and this is when the wool should be gathered. Harvesting Angora involves plucking or shearing the rabbits on Angora farms. Plucking is not what it sounds like; it is essentially combing out the loose/shedding hairs from the undercoat as the rabbit is molting. However, this is a very time consuming process so some farmers resort to shearing.

Camel hair

Camel hair comes from the Bactrian camel, and according to Britannica:

“The hair is not usually gathered by shearing or plucking; it is most often collected as the animal sheds its coat. Both the outer coat and the undercoat are shed at the same time, and combing, frequently by machine, separates the desirable down from the coarse outer hairs.”

This process takes place each spring, which yields about five pounds of wool per camel. China is the world’s largest supplier of camel hair, followed by Mongolia.

Cashmere

Known as a luxury fiber, cashmere comes from cashmere goats, which are not one specific breed. The traditional cashmere goat is the pashmina, but there are numerous other goat breeds that provide cashmere, and nearly all are located in China and Mongolia.

Cashmere is costly because it’s difficult to obtain—the fibers come from the goat’s soft, downy undercoat and must be combed instead of sheared. In addition, the cashmere goat produces a very scarce amount of cashmere wool per year, molting once every spring.

In Mongolia, where 40% of cashmere comes from, cashmere goats outnumber humans eight to one. The increased demand for this fabric, coupled with climate change, threatens ecosystems as more land is being degraded by grazing.

Wear cashmere responsibly by choosing products certified by the Sustainable Fibre Alliance or the Good Cashmere Standard. Or consider buying used items. Some companies are producing pieces with recycled cashmere, which can be certified by the Global Recycled Standard.

Merino

This fiber is considered by many to be the finest wool available. It comes from Merino sheep, which constitutes about half of the world’s sheep population. Merino differs from traditional wool in that it is extremely fine and soft, therefore less itchy and irritating as regular wool can be.

Unfortunately, animal mistreatment is a huge issue in this animal group.

The biggest ethical issue to watch for in merino is mulesing, which is a surgical procedure that removes a section of skin from the backside sheep, often without anesthesia or pain control. Then the open wound is left to heal. The purpose of this brutal procedure is to reduce the risk of a parasitic disease called myiasis, or flystrike.

New Zealand and Europe have banned this practice, but it is still legal in the US, as well as in Australia, who supplies most of the world’s wool.

Choose merino wool labeled as mulesing-free, and/or certified by the RWS or ZQ.

Mohair

About half of the world’s mohair is supplied from South African Angora goat farms. In the United States, farms in Texas are a significant supplier. The shearing process on mohair farms takes place twice a year, in the spring and fall. Note that this breed of goat does not provide Angora wool, which comes from the Angora rabbit, as described above.

But as with the Angora rabbit, there have been frequent instances of animal cruelty brought to light by PETA. Again, I’m not interested in watching, but after an investigation of 12 South African farms, a video displaying the horrific treatment of these goats was released. And like Angora, multiple retailers and designers responded by pulling this material from their products.

This luxury material is known for is softness, strength, and natural lustre. With careful research, it may be possible to find ethically sourced mohair.

Yak wool

Yak wool is being utilized more as a more sustainable alternative to cashmere. This fiber is collected from yaks in a similar method used for cashmere, and is said to be comparable in softness and warmth, which is not surprising since yaks can survive at temperatures as low as -40 degrees Celsius. However, the fibers are darker and more coarse, making them more difficult to dye.

This large animal’s grazing habits are kinder on the ecosystem than cashmere goats, who uproot plants as they eat. In contrast, yaks only consume the leaves, making it easier for pastures to regrow. They also graze at a higher altitude, not contributing to the degradation of grasslands where the goats feed.

Go Green

Do your research on wool sourcing before purchasing a product, and buy certified products if possible.

Semi-synthetic fabrics

Rayon

The semi-synthetic fabric category can be a bit confusing, but know that just about every type of fabric in the category is some form of rayon.

Rayon is a broad term that covers fabrics formed with cellulose from a plant source. This can be any type of plant, such as bamboo, but rayon most comes from wood pulp, typically beech, pine, or eucalyptus. Being plant-based, this material is technically biodegradable, but undergoes such a chemically intensive process to transform into a fabric that it is considered semi-synthetic with varying degrees of biodegradeability.

There are three types of rayon: Viscose, Modal, and Lyocell.

Viscose

Rayon viscose was developed as a cheaper alternative to silk. It is cheap to produce, therefore use is very widespread. If a clothing tag simply lists ‘rayon,’ it is viscose.

Viscose is the least environmentally friendly type of rayon because it is processed with very high concentrations of chemicals. The viscose rayon industry has a long history of endangering worker health and causing significant environmental pollution, the main culprits being carbon disulfide and sulfuric acid. In fact, rayon factories created so much pollution through wastewater that the EPA caused them to eventually shut down, and rayon is no longer produced in the United States.

Rayon fibers actually contribute to almost 60% of the fibers found in the deep ocean areas of contamination.

In addition, the wood harvested for viscose often does not come from sustainably managed forests. It is estimated that 30% of the rayon and viscose going into clothing is sourced from endangered and ancient forests. The production of viscose also uses a large amount of water.

Modal

Modal is second generation rayon fabric made from beech tree pulp. The fabric is soft, stretchy, and stronger than viscose. There is a long list of benefits: it is breathable and moisture wicking, making it ideal for workout wear; it also drapes well, doesn’t pill, retains color well, resists shrinking, doesn’t crease, and is biodegradable. This fabric is processed much like rayon, with some key differences. These variations usually include less chemical use, but ultimately the sustainability of modal is determined by individual manufacturer processes.

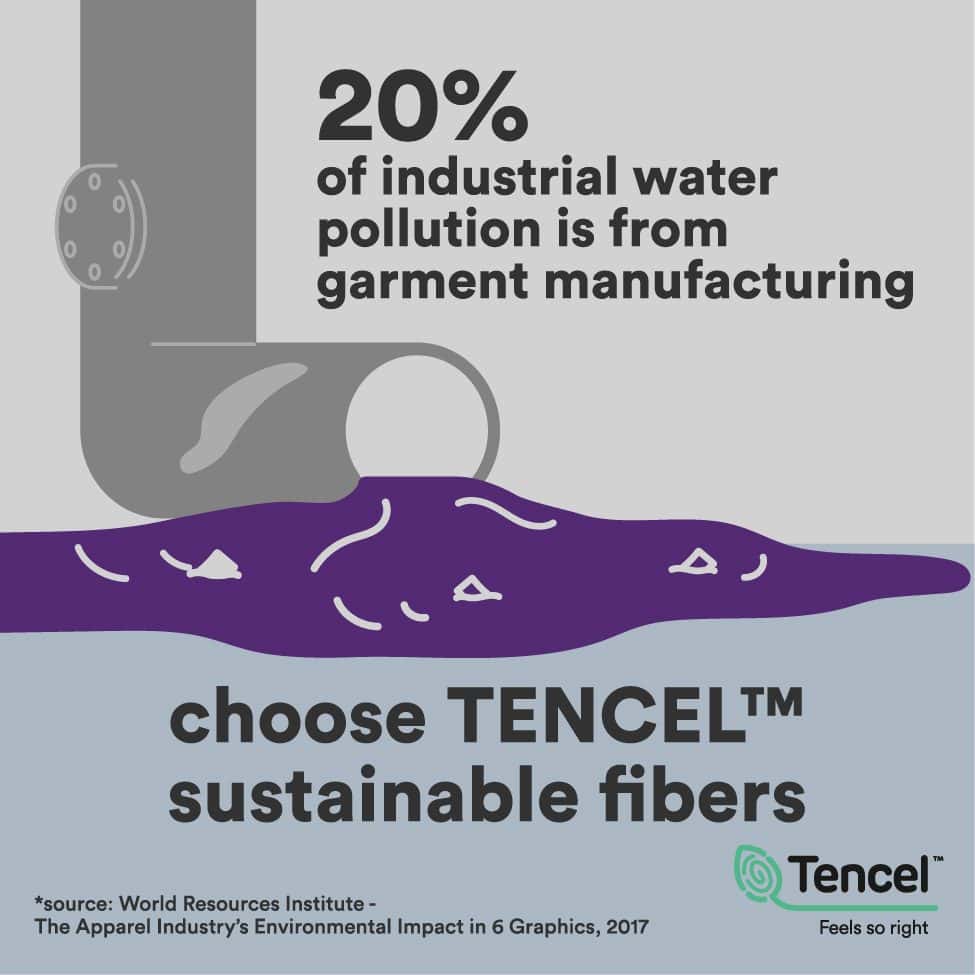

The gold standard for sustainable modal, as well as lyocell (described below), is produced by the Austrian company Lenzing AG, based in a city of the same name. This company produces all three types of rayon, branded as TENCEL, with the most eco-friendly practices of any other in the rayon market. Their factories utilized renewable energy and trees are sourced from FSC-certified forests, which don’t require herbicides and pesticides. The yield of fibers from this process produces up to ten times more content than what can be taken from the typical cotton field. It also requires less than 20 times less water than cotton.

Lenzing employs a spin-dyeing process, which results in significantly less pollution than conventional dyeing. One study found that this uses 50% less energy and has a 60% lower carbon footprint, in addition to requiring only half the water.

Lyocell

The third generation rayon is lyocell, created with cellulose from eucalyptus wood pulp. Eucalyptus trees grow quickly, without additional irrigation or pesticides, and can thrive on land no longer fit for food or other uses.

Recycled fabrics can also be used in lyocell production.

Lyocell fabric has the same qualities as modal, and is the strongest of the rayon fabrics. It is also the most sustainable of these, and a great overall choice for eco-friendly fabric—again, depending on production practices.

Lenzing’s TENCEL lyocell is the top choice. Their production of lyocell uses less toxic chemicals that are recirculated in a closed loop system. 99% of solvents do not leave the facility, in turn eliminating environmental pollution. Clothing can also be recycled to create new lyocell fiber.

To summarize, modal and lyocell are the generic names; TENCEL is the brand name for these fabrics produced by Lenzing. Find companies that utilize TENCEL sustainable fabrics in their products in this brand directory.

Acetate

Also called Cellulose Acetate (CA), this material is derived from plant cellulose, much like other rayon fibers. And like traditional rayon, the cellulose fibers are treated with multiple harsh chemicals, including acetic acid, acetic anhydride, and sulfuric acid for production, along with acetone for fiber formation.

As a fabric, this semi-synthetic material is smooth and silk-like, quick-drying, and doesn’t shrink. It also wrinkles easily and can melt when it gets too hot. That is because acetate is a thermoplastic, which means with heating, it becomes pliable or moldable and solidifies upon cooling. This process is reversible, allowing thermoplastics to be reshaped and recycled multiple times without significantly altering their chemical properties. Therefore this material is also frequently used to produce accessories like jewelry or sunglasses.

The biodegradeablility of acetate varies depending on percent of plant material in the final product, as well as conditions where it is found. In the worst cases, this fabric can contribute to microplastic pollution as other synthetic fibers do.

Go Green

Avoid viscose rayon. Acetate is a better choice than 100% synthetic fabrics, but modal and lyocell are the best semi-synthetic fabric choices; ideally choose TENCEL branded modal and lyocell produced by Lenzing.

Synthetic Fibers

Nearly all synthetic fibers are fossil fuel-based and their production requires more energy and produces considerably higher greenhouse gas emissions than natural materials. In addition, significant amounts of chemicals are used during the manufacturing process, including synthetic dyes, since natural dyes are not effective on synthetic fibers. This results in these products emitting toxic polluntants throughout every phase of their life cycle.

Synthetic fabrics use do less water to produce than their natural fiber counterparts, but this benefit is negated by the significant contribution to the world’s microplastic problem.

Being based on petrochemcials, synthetic fibers are simply a type of plastic, and therefore not biodegradeable. A natural fiber such as cotton is made of cellulose, and is able to biodegrade in wastewater, saltwater, and freshwater, not contributing to microplastic pollution. In a recent study conducted by Cotton Incorporated, a 100% polyester sample saw minimal deterioration, while a 100% cotton sample had disintegrated 76% in wastewater in 250 days. By comparison, rayon disintegrated 60% in the same conditions and timeframe, and polyester disintegrated only 4%.

Synthetic fibers leave behind microplastics and leach chemicals into soil and water sources. This is especially unfortunate as 69% of all clothing is composed of man-made materials, the majority of that being polyester.

Laundering synthetic fabrics has a much more significant environmental impact that you probably realized. With every load, an average of 700,000 tiny plastic microfibers are released into the water. These particles are too small to be filtered out through waste water treatment plants. It is estimated that up to 35% of microplastics in the ocean and 71% of microplastics in rivers come from synthetic clothing. In your own home, textile microplastics compose 33% of the dust floating around.

The fact that these materials are cheap to produce lends to their wide use and popularity despite the environmental implications. Purchasing textiles made from synthetic materials also perpetuates dependence on fossil fuels.

Read more about plastics here.

Polyester

Polyester is the most widely used fiber in the world, with a market share of 54% of global fiber production in 2021. It accounts for 80% of all synthetic fibers used.

As with any all synthetics, polyester production is a high energy, high polluting process. One study reported that 112 MJ of energy is required to manufacture 1 kg of polyester, about double that of cotton. Polyester production emits VOCs, and one study found that it gives off nearly three times more carbon dioxide than cotton.

Many companies have started making fabrics from recycled polyester, which primarily comes from PET plastic bottles. While preferred over virgin material, it certainly doesn’t address the ultimate end of life issue of these non-biodegradable materials.

Nylon (Polyamide)

The production of nylon creates nitrous oxide, a significant greenhouse gas. At the end of its life cycle, nylon is very difficult to recycle and if burned, emits poisonous gases such as dioxins, nitrous oxide and hydrogen cyanide.

Elastane (Spandex)

Elastane is made from polyurethane, a type of plastic and known carcinogenic. You may also know this by one its brand names, Lycra. We are all familiar with this stretchy fabric, from workout wear to the added stretch to denim and other fabrics. It is rarely used alone, as it is usually mixed with other types of fibers to add its stretchy quality.

Acrylic

Due to its warmth and wool-like feel, acrylic is generally chosen as a cheap alternative for cashmere wool. Unless a sweater is made from 100% wool, it almost assuredly has acrylic blended into the material. This fiber is made from acrylonitrile, a chemical rated as a probable carcinogen by the EPA. Toxic fumes are emitted during its production process.

Acrylic fibers are one of the major contributors of microplastics in the marine environment. According to a study, acrylic fabrics washed in domestic washing machines released nearly 730,000 tiny synthetic particles per wash, which, via the sewage network, reached the sea, five times more than polyester–cotton blend fabric, and nearly 1.5 times as many as polyester.

One group of scientists found acrylic to be the worst fiber in terms of environmental impact and ecological sustainability.

Go Green

While recycled synthetic fabrics are better than virgin materials, they are still plastic-based, shed microfibers, and will ultimately end up in a landfill. Synthetic fibers are among the most unsustainable fabrics around, and are the most plentiful. It is extremely difficult, but avoid clothing and textiles made from synthetic fibers as much as possible.

Despite the number of resources required by natural fibers, my research has led me to conclude that these renewable materials are the superior choice given the serious, long-lasting negatives of synthetic materials. In addition, natural fibers generally contain less chemicals than those that are man-made.

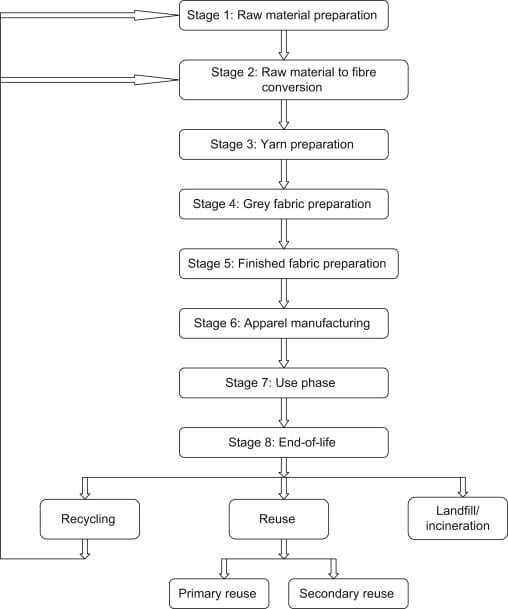

Fabric Production

When the United States moved manufacturing overseas, the associated pollution and greenhouse gas emissions were effectively transferred to countries with fewer pollution controls. Manufacturing practices in these less-developed countries are generally less efficient than in developed nations, often resulting in higher energy, water, and material consumption. This inefficiency not only increases production costs but also exacerbates environmental damage. By enhancing manufacturing efficiency in these countries, there are significant opportunities to reduce costs and improve environmental outcomes.

Each step in the fabric production process uses resources and some create more pollution and carbon emissions than others. Even the most sustainably cultivated natural fiber can have its eco-friendly benefits negated by poor processing techniques.

Weaving

Environmental concerns related to weaving are greater than those arising from knitting owing to the increase in the number of processes and machines involved. A variety of weaving machines are currently available, each with its unique processing methodology, energy needs and environmental impacts. Additionally, the strength and quality of a weave is a big factor in long lasting, durable fabrics.

Some fabrics can be handwoven. One of the key factors contributing to the sustainability of handloom weaving is that it operates without the need for electricity. This results in clear environmental benefits, as it significantly reduces energy consumption and minimizes resource usage compared to powerlooms. While handloom weaving is a slower process, it allows for lower minimum production quantities, making it easier to produce only what is needed and reducing waste at the end of each season.

Many of the words you see under textile product descriptions are actually referring to the type of weave used to construct the fabric. This can be confusing, as a type of weave does not indicate what material is used. Two items made from the same weave type can be made of completely different types of fibers, or a blend of more than one. For example, chiffon is a type of weave; a chiffon dress might be made of natural fibers such as cotton or silk, or synthetic fibers like nylon or polyester.

I didn’t know much about this before my research, so I find it helpful to understand the difference. I’ve also noticed that when shopping online, many times ‘material’ filter options actually include a mix of actual materials along with weaves, which adds to the confusion.

There are three main types of weave used for fabrics.

1. Plain weave

Plain weave is the most basic fabric construction method. A loom is used to create its criss-cross, over under pattern of threads, resembling a checkerboard. This makes for durable, strong fabric that resists pilling. Plain weave items are not stretchy and retain their shape, but crease easily. The fabric is generally coarser and the same on both sides. It is usually more expensive than knit because production is more time-consuming.

2. Twill weaves

Twill is characterized by its diagonal weave. These weaves have a distinct front side, which is often darker colored, with a lighter back. Twill has high thread count, which means that the fabric is opaque, thick, and durable. It doesn’t wrinkle easily and hides stains well.

3. Satin

Satin is has a shiny surface on one side, with a duller surface on the other. This fabric drapes, is wrinkle resistant, and snags easily. Originally, satin was made using silk, but today’s satin is often made from polyester and rayon.

Other weaves

- Brocade

- Corduroy cotton

- Jacquard

- Gauze

- Velveteen

Faux fabrics

While vegan fur and leather are animal friendly options, they are certainly not ideal for the planet.

Faux fur is generally a blend of blend of synthetic fibers like polyester, modacrylic, and acrylic fibers. Read more about faux fur here.

Synthetic leather, aka pleather, is usually made from polyurethane (PU) or polyvinyl chloride (PVC)–arguably the worst and most toxic type of plastic.

Knit Fabrics

Knitting is a relatively simple process that uses a single machine to convert the yarn to grey fabric. There is a lack of comprehensive data on life cycle assessment studies specifically for the knitting sector and the critical points within the process. Examples of common knits include:

- French Terry

- Fleece

- Jersey

- Chenille

- Sherpa (real sherpa is made from sheepskin)

Dyeing

Around 20% of wastewater worldwide comes from fabric dyeing and treatment.

Synthetic fibers can be difficult to dye, so manufacturers use synthetic dyes to permeate the fibers. The good thing about synthetic dyes is that they are very stable in light and high temperatures and can resist even environmental degradation. This is, however, also what makes them bad for the environment.

Synthetic dyes have been found in water, underwater sediment, and even the fish themselves. Being widely used, it comes as no surprise that they have found their way not only to aquatic environments but also into the soil. Researchers believe the toxicity and pharmacological tendencies of these substances are cause for concern.

Finishing

The goal of the finishing process is to protect fabrics from natural processes as well as to give them performance characteristics they normally don’t possess, such as the ability to repel water.

All natural fibers are susceptible to microbial decomposition by organisms like bacteria, fungi, mold, and mildew.

mechanical and chemical processes employed commercially to improve the acceptability of the product. Finishing processes include preparatory treatments used before additional treatment, such as bleaching prior to dyeing; treatments, such as glazing, to enhance appearance; sizing, affecting touch; and treatments adding properties to enhance performance, such as preshrinking. Newly formed cloth is generally dirty, harsh, and unattractive, requiring considerable skill for conversion into a desirable product.

processes like bleaching, softening, water or fireproofing, antibacterial and antifugal finishes, brushing like cotton antimicrobials, flame retardants, stain resistant chemicals

Also be on alert for greenwashing. Many products today may profess to be “eco-friendly” or “sustainable,” but with little substantiating evidence. For instance, says Find Osther of Kvadrat, many fabrics will claim to be made from “recycled” content, but will actually contain negligible amounts. And, she says, many so-called “natural” dyes require more chemicals than artificial ones.

A 2022 Toxic-Free Future study tested outdoor apparel, bedding, tablecloths and napkins from 10 major retailers and found that 72% of products marketed as stain- or water-resistant contained PFAS. In contrast, all of the items that weren’t marketed as stain- or water-resistant were PFAS-free.

Labor Practices

Conclusion

Following the supply chain of any one product is difficult, and textiles are no exception. As consumers we can only do our best and find companies and brands we trust. As I’ve shopped for new clothing, I have found just how hard it is to steer away from synthetic fabrics. I am a picky shopper anyway, and it’s so disheartening to find something I really like only to check the tag and discover it is made from polyester.

In addition to buying eco-friendly pieces, there are several other important strategies to decrease textile waste, including:

- Refrain from compulsive shopping and buy only what you really need. Consider shopping second-hand and seek to repair or repurpose items where possible.

- Prioritize quality over quantity. Frequently replacing numerous items, even if sustainably-made, uses more resources than a single well-made piece.

- Read the labels on your clothing and other textiles and make sure you follow the instructions and care for them accordingly to prolong their life. Learn more about how to take care of your clothing and other textiles here.

- Recycle textiles that are no longer usable.

Learn more about how to choose sustainable textiles, including sustainable clothing and home textiles.